Terrazzo Flooring: Origins, Types, and Key Advantages

2025-05-16 11:20

What Is Terrazzo and What Is It Made Of?

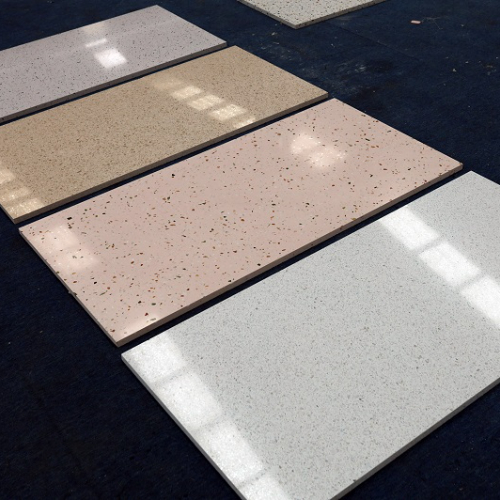

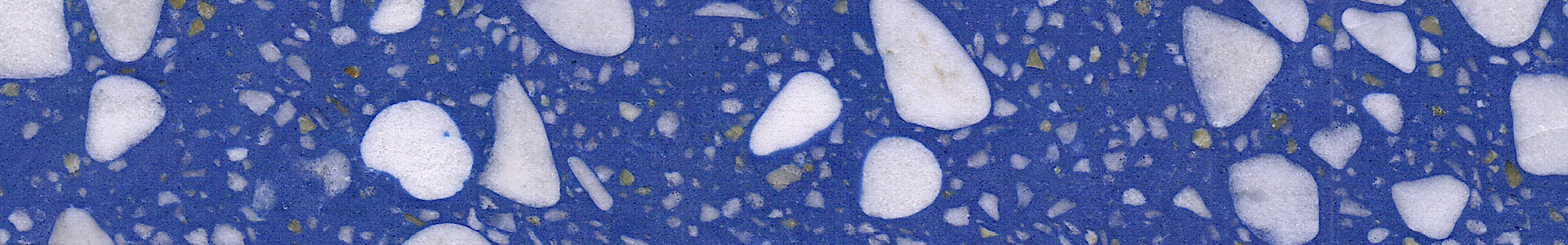

Terrazzo is a type of flooring made by mixing decorative stones. These stones can be marble, quartz, granite, or recycled glass. They set them in a binder, which usually contains cement or epoxy resin. Once cured, the surface is ground and polished to a smooth, glossy finish.

People value it for its smooth look, strong durability, and customizable design. It comes in many colors and patterns, making it a popular choice for homes and businesses.

Modern it mainly comes in two forms:Cast-in-place terrazzo, poured and finished on-site for a seamless surface.Precast terrazzo tiles or slabs, manufactured in factories and installed like ceramic tiles—ideal for shorter construction timelines.

A Brief History of Terrazzo

Terrazzo originated in 15th-century Venice, Italy, when stonemasons embedded marble offcuts into lime-based mortar to pave terraces. This early version of was cheap and good for the environment. It made the most of construction waste.

The material became popular in the United States in the early 1900s. This was because of the invention of electric grinders and divider strips.

Iconic structures like the Empire State Building and Radio City Music Hall feature terrazzo floors. Today, is becoming popular again. This is because of new resin technology and the need for eco-friendly building materials.

Types of Terrazzo: Inorganic vs. Epoxy Systems

Terrazzo flooring is typically categorized into two major systems:

1. Inorganic Terrazzo (Cement-Based)

Cured with high-quality white cement imported from Italy.

Dongxing Group has made a significant advancement. They have created ultra-thin inorganic terrazzo slabs that are only 10mm thick. This gives clients more choices.

100% VOC-free with excellent breathability.

Suitable for both indoor and outdoor applications.

Superior resistance to fire, frost, corrosion, and heavy wear.

Ideal for large-scale surfaces and timeless color schemes.

2. Epoxy Terrazzo (Resin-Based)

Uses 100% solid epoxy resin.

Lightweight and thin-layered (approximately 6–9mm), with a fast curing time.

Offers greater flexibility in color and design—ideal for bold, modern aesthetics.

Perfect for high-traffic indoor areas such as malls, schools, hospitals, and airports.

Dense and nonporous—delivers excellent stain and moisture resistance.

Where Is Terrazzo Flooring Used?

Thanks to its durability, low maintenance, and upscale appearance, many people widely use it in:

Airports, subway stations, hospitals, and schools: High-traffic zones benefit from terrazzo's abrasion resistance and antimicrobial properties.

Hotels, office buildings, and shopping centers: Enhances interior aesthetics while minimizing long-term maintenance costs.

Residential settings: More people are choosing it for bathroom floors, kitchen countertops, stair treads, and feature walls. This is because it is water-resistant and offers design flexibility.

Aesthetic and Functional Benefits

Terrazzo is not only practical but also visually striking. It features a polished surface that reflects light and enhances architectural character. Designers can incorporate marble chips, recycled glass, shell fragments, or metal pieces to create artistic and distinctive finishes.

When properly installed, terrazzo flooring can last for over 75 years—and sometimes much longer. One famous example is the terrazzo floor in George Washington’s home, which has lasted over 280 years. Epoxy terrazzo is easy to clean every day. In contrast, cement-based terrazzo needs sealing now and then for long-term protection.Terrazzo flooring, bathroom tiles, or a terrazzo countertop are strong and stylish options.Terrazzo flooring, bathroom tiles, or a terrazzo countertop are strong and stylish options.

Is Terrazzo Environmentally Friendly?

Absolutely. Terrazzo is one of the earliest building materials to incorporate recycled content. Today’s terrazzo systems go even further:

They use 100% recycled aggregates, including glass, shell, or construction waste.

Employ low-VOC or zero-VOC binders, especially in cement-based terrazzo.

Have exceptionally long life cycles, reducing replacement waste.

Meet or exceed LEED and other international green building standards.

For example, manufacturers like Dongxing Group utilize natural stone waste to produce inorganic terrazzo slabs, combining sustainability with modern design.